Textile architecture meets Art: When buildings become works of art

Textile architecture and membrane construction – How high-tech materials enable extraordinary structures

Textile architecture meets art when buildings become impressive works of art.

The use of textiles as dwellings – see tents – dates back to the earliest times of human history and remains a proven method of construction today. The properties of textile materials, such as lightness, adaptability, and the ability to dismantle them, make them an ideal choice for constructing temporary shelters that can offer protection from wind, UV radiation, and moisture.

In modern architecture, the principles of tent construction have been revived and refined – adapted not only for temporary structures but also for permanent constructions.

Using textile materials such as membranes and fabrics, architects can express their creativity in extraordinary projects. The assembly of these special building elements opens up new design possibilities and creates a fascinating fusion of architecture and art .

What is textile architecture?

In the past, structures made from traditional natural fibers, such as tents, were considered typical examples of textile architecture. However, in modern times, textile architecture relies on technologically advanced high-tech fabrics in the field of textile engineering.

Membrane construction

When discussing textile-based architecture, the focus is generally on the design of building envelopes . Textile construction utilizes flexible materials such as membranes and textiles to create unique and innovative building structures – this is also referred to as membrane construction . Cables are frequently used as supports.

A unique property of membranes is their ability to absorb tensile forces under compressive stress and transmit them to the outside. The force distribution occurs through the membrane itself – this is known as the "membrane tension state." Thanks to this special property, they are extremely resistant to stresses of all kinds.

The ropes are flexible and pliable and serve as transmission elements for tensile forces in textile architecture. Their tension allows the membranes to be stretched taut. One challenge lies in determining the correct amount of tensile force to protect both the rope and the membrane from damage.

High-performance textiles and composite materials

This interplay of architectural design and state-of-the-art technical or industrial textiles allows architects to explore entirely new design possibilities and transcend traditional boundaries.

In the context of textile architecture, the advantages of fabrics in terms of their flexibility, lightness, and versatility are utilized. The use of these materials allows for the creation of organic forms and complex structures that would not be possible with conventional building materials.

The use of durable and high-performance materials makes it possible large spans and cover large areas . For this reason, textile construction has established itself as a highly specialized sector.

The special static requirements for the fabrics themselves, such as wind loads or weather resistance, require extensive engineering know-how regarding the suspension, fastening and tensioning of the textile components.

To meet these challenges, the production and cutting of the textile surfaces follow complex cutting patterns, incorporating state-of-the-art computer technology and taking static factors into account.

Textile facades as bioclimatic building envelopes

Depending on their texture, layout, translucency, color or print, textile facades realize your projects in a unique way of textile architecture

Acting as a second skin for the building, they provide a bioclimatic building envelope, controlling solar radiation and heat loss – thereby significantly increasing the energy efficiency of the buildings. SMC2 , a pioneer in this industry, designs textile curtain walls, visually enhancing existing buildings and the surrounding living space.

© SMC2

Textile facades can be wonderfully combined with other facade types (such as wood, steel, or mineral composite front panels) to create individual architectural styles. Their curved shapes practically invite imaginative implementation of innovative ideas.

The use of textile roof coverings gives buildings a unique look characterized by flowing and airy forms. This feature is often associated with contemporary architecture.

The combination of the delicate wood or steel construction and an elegant textile surface creates numerous possibilities for structural and architectural design elements.

The interplay of light and shadow

The use of textile membranes allows natural light and shadow to be used in a special way to living spaces a new feel-good atmosphere.

By projecting light back onto interior or exterior surfaces, buildings can be given a vibrant appearance. As soon as it gets dark, the building's appearance transforms in a fascinating way. This type of lighting architecture perfectly complements a textile facade and opens up new possibilities for innovative communication.

SMC2 offers a comprehensive service package in this area with high technical standards, which includes all the necessary components for a successful project: structural calculations, thermal and acoustic calculations and architectural design including interface management are available.

Construction of a textile facade for a department store in Brignais

© SMC2

The storefront of the department store in Brignais (France) is visually emphasized by its robust steel structure and membrane covering. To ensure visibility even during the day, the company logo was integrated into the center of the facade using screen printing.

As soon as it gets dark, LED lighting colorful illumination of the building.

The open-air sports hall is another area of activity for SMC2, which promotes the construction of economical and ecological sports facilities. A covered recreational facility with free access, usable year-round, is both sustainable and economically efficient. It offers sports opportunities in an indoor-outdoor environment, thus enabling activities regardless of the weather.

A brief history of textile membrane construction

The history of textile architecture is closely linked to developments in the architectural world. As early as the 1960s , architects began to increasingly integrate textiles into their building projects. The use of textile materials such as membranes and networks made it possible to design building structures that were lighter and more flexible.

This led to a new era in architecture, in which buildings became true works of art.

Lars Meeß-Olsohn is an architect who has significantly contributed to the development of textile architecture . As the founder of the company textile-architektur GmbH, he has realized numerous innovative projects and exerted a far-reaching influence on the industry.

His visionary ideas and products have revolutionized construction with textile materials. For the past 12 years, his TEXTILE-ARCHITECTURE has been providing planners and building owners with comprehensive information about the possibilities of building with innovative textiles/films and their high-quality processing – through participation in major trade fairs, an annual brochure, and regularly held symposia.

Basic rules, methods and design principles

Textile architecture is generally supported by columns and cables , which can also be made of steel. In membrane construction, three types of support crucial, which are used in cable structures depending on the material and the size of the area: point supports, linear supports, and planar supports .

With point-like support, the membrane has high and low points; with a linear shape, it is designed in an arc shape; while a planar support is achieved with throat/ridge ropes.

The "primer" for textile architecture, entitled TensiNet European Design Guide for Tensile Surface Structures, provides information on which membranes should be used in a construction project. The publication is issued by the renowned TensiNet Association, which specializes in all aspects of building with tensioned materials such as ropes and membranes.

Structure-based membranes: This construction method refers to the use of support structures to support the membrane, instead of relying on cables. A notable example of this is the roof of Gondwanaland in Leipzig, which consists of ETFE foil cushions integrated into a robust steel structure.

Tensioned structures are a construction method in which membranes are tensioned linearly or at specific points using masts and cables. This can be done, for example, according to the basic principles of saddle surfaces or elevation surfaces.

Air-supported structures use an air support blower to create overpressure under the membrane structure, allowing it to float. These air-supported halls do not require any additional load-bearing elements. The structure typically consists of several layers of membrane, insulation, and soundproofing materials.

Air-supported structures are often used as temporary roofing at sporting events. Increasingly, they also serve as covers for outdoor pools, allowing them to be used year-round.

The design principles of textile architecture also allow for the use of steel construction . However, there are also more natural options, as demonstrated by HP Gasser AG from Switzerland. Their specialty is timber membrane halls – a construction method in which the roof rests on a framework of wooden poles supported by tensioned membranes. Depending on the purpose and aesthetics, steel can even be used for floor supports – for example, as a terrace roof.

Notable examples of textile architecture

Ferrari World Abu Dhabi

A well-known example of textile architecture is Ferrari World Abu Dhabi , which used an impressive textile membrane to design the roof of the building.

Beneath its iconic red roof in the heart of Yas Island lies the world's first Ferrari theme park and the largest attraction of its kind. The park celebrates the passion, excellence, performance, and technological innovation that Ferrari has established over the years and represents today.

Photo by Floness, CC BY-SA 4.0, via Wikimedia Commons

As a state-of-the-art leisure attraction, the world-renowned architectural firm Benoy created a building whose curved shape reflects a Ferrari and was directly inspired double-curve side profile of the Ferrari GT body

Tubaloon, Norway

Every summer, the Kongsberg Jazz Festival opens its gates, and with them, the stage for the artwork Tubaloon . Within three weeks, this membrane sculpture is erected in the historic center of the Norwegian town to serve as the main stage for the renowned music festival. It was designed by the American-Norwegian architectural firm Snøhetta .

Photo by sigmundg, CC BY-SA 3.0, via Wikimedia Commons

Tubaloon consists of a PVC fabric construction which is stretched over the static structure like a skin – despite its size (20 meters high and 40 meters long) it appears light due to its white membrane fabric and its support ropes on the ground.

The temporary installation lends the jazz festival a unique atmosphere, transforming it into a special experience amidst the historic backdrop of Kongberg. Designed to reflect the festival's theme, the stage evokes wind instruments and the human inner ear, giving it an organic and sculptural appearance.

A translucent membrane shell can be illuminated to suit different moods, adding extra flair to the installation.

During concerts, the shell-shaped fabric ensures excellent sound without amplification, which significantly contributes to the success of the jazz festival.

Allianz Arena, Munich

The undisputed highlight of Munich's Allianz Arena – home of FC Bayern – is its innovative membrane structure: a significant achievement in textile architecture. The facade consists of a total of 2,800 pneumatically prestressed cushions made of ETFE film (ethylene tetrafluoroethylene). These have spans of up to an impressive 4.25 meters, clearly demonstrating just how magnificently this stadium was designed.

photographed by Sönke Biehl, CC BY-SA 2.0, via Wikimedia Commons

The membrane cushion material is extremely translucent and weighs just 350 grams per square meter. It also exhibits high resistance to harmful environmental influences, especially UV light . Thanks to the use of fans, the cushions can be kept sufficiently inflated at all times – even in adverse weather conditions such as strong winds or snow.

The transparent roof cushions allow natural daylight to enter the stadium, while the facade cushions remain white. This allows the entire building to be illuminated by an impressive array of approximately 25,000 fluorescent lamps in various colors – depending on which team is playing.

Venezuelan Pavilion by architect Fruto Vivas

After Expo 2000 in Hanover, the pavilion designed by Venezuelan architect Fruto Vivas dismantled and transported to Venezuela in over 50 containers. It took six years to find a new location. During this time, the membranes had to be stored under extreme conditions – they were exposed to high temperatures of over 80°C – but remarkably, all the original membranes could be reused.

Photo by Andrea Mar Luna, CC BY-SA 3.0, via Wikimedia Commons

Applying a protective lacquer gives PVC-PES membranes an anti-stick coating, making their surface dirt-repellent and easy to clean for several years. Depending on climate, application, and stress, the material's lifespan can reach up to 20 years.

PVC-PES is a versatile fabric with high tear resistance and exceptional flexibility, making it suitable for a wide range of applications. It is particularly popular for roof and facade construction. One of PVC-PES's key properties is its relatively high light transmission, as well as its "flame-retardant" fire rating.

Furthermore, it impresses with its good kink resistance.

Reception building “Mitoseum” in the Kleinwelka Dinosaur Park

The concept for the reception building in the park is based on the symbolic representation of the primordial cell and its division as the origin of life . The process of mitosis serves as inspiration for the delicate construction, which harmonizes with the natural environment and thus embodies the essence of bionics. The evolution of life is thereby made visible.

The realization of this design concept results in a MITOSEUM that is visible far beyond its boundaries and awakens immediate expectations upon arrival. The building serves both as a project idea and a model for a successful symbiosis between nature and architecture – characterized by refined design and balanced structures.

Photo by Stefan Kühn, CC0, via Wikimedia Commons

Thus, this structure not only reflects an architecturally innovative approach, but also testifies to a profound understanding of how life has evolved – namely, starting from the lowest common denominator: a single cell.

The six phases of mitosis, beginning with interphase and ending with telophase, serve as inspiration for the architectural design of this reception building. Their characteristics are clearly recognizable through the building's height and volume, even from a great distance.

The translucent outer skin is made of ETFE foil in natural colors, symbolizing the beauty of life itself. This distinctive design is significant for the unique appearance of this place, creating a strong sense of identity – a true eye-catcher!

The building has deservedly received several awards, including the German Galvanizing Award 2017, 3rd place

German Design Award 2018, Winner Excellent Communications Design – Architecture

AIT Award 2018 – Special Mention I Category “Sport/ Leisure” and the Heinze Award 2017 – 1st place Audience Award.

Swiss Pavilion at EXPO Shanghai 2010

The Swiss pavilion at EXPO Shanghai 2010 was surrounded by a textile facade, which can be viewed in a broader sense. The facade consisted of a steel mesh made with galvanized wire ropes four millimeters in diameter, covering an area of 3,800 m² and reaching a height of up to 15 meters.

Photo by Swiss Federal Department of Foreign Affairs, Public domain, via Wikimedia Commons

Environmentally friendly polycarbonate formed a total of approximately eleven thousand cells of this textile facade and generated electricity for the operation of the pavilion via solar technology.

Water Cube – Beijing National Swimming Center

The Aquatics Centre, which hosted the swimming competitions at the 2008 Beijing Olympics, is located along Olympic Boulevard, along with other sports facilities. This boulevard extends the central axis of the Forbidden City, stretching an impressive 177 meters along each side and reaching a height of 31 meters above street level. The building is therefore not only an architectural highlight of Beijing but also one of its largest structures.

photographed by A. Aruninta, CC BY 3.0, via Wikimedia Commons

With its shimmering blue facade, the National Swimming Center engages in a dialogue with the red National Stadium – an oval symbol of China's sporting power during the Olympics. Through their mutual complementarity, the two buildings impressively demonstrate the principle of Yin and Yang : two different elements together form a whole – harmoniously combined to create something unique.

The house is deeply rooted in Chinese tradition and mythology. The architect uses water as a structural and thematic leitmotif to create a connection, drawing on the square – the archetypal form of the house in China. The construction is based on a geometric structure: the foam of water in its atomic state. The result is a lightweight building with impressive stability.

The cube, which covers an area of 80,000 m², is divided into three rectangular functional areas by its double-shell ETFE envelope and can also be experienced from inside the building. Arup developed the structure for the Watercube on the computer, based on the Weaire-Phelan structure – a phenomenon observed in crystals – using rotation and several sectioning operations. The 3D model served as a binding specification for all parties involved during the construction process.

Materials used in membrane construction

Membrane construction involves the use of technical or industrial textiles that differ significantly from fashion textiles. These materials are used in various applications and are specifically selected for their functionality.

Unlike conventional fabrics, these textiles are robust, resistant to environmental influences such as moisture and sunlight, and temperature-resistant. They therefore meet higher standards of quality and performance than fashionable garments.

The weaving of these high-quality fibers creates a membrane with a special property: it is waterproof or airtight, yet breathable. This makes it ideal for various constructions such as tents, roofs, or even protective clothing in the medical field.

Overall, membrane construction combines textile innovation with functional design – an important aspect in modern building and construction.

Technical textiles include:

- Technical cotton fabrics, acrylic and polyester fiber fabrics, and sun sailcloth: There is a wide variety of fabrics that can be used for technical cotton fabrics. Acrylic and polyester fiber fabrics, as well as sun sailcloth, are some of the most popular options on the market. These materials are perfect for indoor use or for covering limited areas.

- Polyester fabric with PVC coating (PES-PVC): Polyester fabric coated with PVC (PES-PVC) is ideal for both indoor and outdoor use. It is highly flexible and can therefore be folded or gathered without creasing. Furthermore, this material offers excellent fire-retardant properties and effective UV protection. However, PVC is generally prone to dirt and should therefore be protected with a coating such as fluorinated lacquer. Nevertheless, due to its extremely robust nature, PES-PVC exhibits enormous tear resistance – even if it tears, there is usually no risk of further tearing. However, disposal of used PES-PVC is difficult, if not impossible, due to toxic additives in the fabric.

- Fabric made of fiberglass and PTFE: The abbreviation "PTFE" stands for polytetrafluoroethylene. Fabric coated with this material cannot be bent or gathered – it remains rigid in its shape. Compared to polyester with PVC, it has lower tear strength and tends to crease more easily. For these reasons, this material is not suitable for structures like event halls, which need to be frequently assembled and disassembled; instead, it is preferred for long-term structures.

- Silicone-coated fiberglass fabric: Unlike PTFE, silicone proves to be an excellent coating alternative due to its high flexibility and therefore extreme resistance to bending stresses.

The silicone layer also exhibits remarkable resistance to UV radiation and can easily withstand temperatures up to 70 degrees Celsius. Thanks to silicone's low tear resistance, the structure's stability is maintained even in the event of a tear. Another advantage: Both the fiberglass-based substrate and the silicone surface are recyclable – an environmentally friendly aspect. However, it should be noted that silicone-coated surfaces tend to become charged and can therefore attract dust particles. To prevent this, the use of an antistatic varnish is recommended. - ETFE films: these films are used as cushioning in various applications, such as open-air halls, swimming pools, and greenhouses. Their special properties include low weight and high light transmission. For example, the newly built Gondwanaland in Leipzig is roofed with ETFE films, while the famous Water Cube in Beijing consists of 100 tons of this special plastic film. Furthermore, the material is characterized by its dirt resistance and the possibility of environmentally friendly disposal.

The aesthetic effect of textiles in an architectural context

In an architectural context, textiles unfold an aesthetic effect that can significantly shape the character of a building. The fusion of textile architecture and art allows for a play with colors, patterns, and transparencies , creating a unique atmosphere.

The use of membranes and net-like structures creates exciting visual effects and opens up new possibilities in architectural design.

Sustainability: Is textile architecture an environmentally friendly alternative?

In today's world, where environmental protection plays an increasingly important role, the question arises whether textile architecture can represent an environmentally friendly alternative to conventional construction. The combination of sustainability and textile design could be a promising solution.

Textile architecture opens up new possibilities in the construction industry, both in terms of aesthetics and sustainability. The use of textile materials enables flexible construction methods that offer both economic and ecological advantages.

This includes simpler assembly, flexibility in design, and a reduced amount of building materials required.

The use of textiles can achieve higher energy efficiency thermal insulation and effective light control . Furthermore, textile architectural elements are recyclable and thus contribute to a more sustainable construction industry.

Textile architecture also enables efficient energy generation through the use of solar sails or photovoltaic membranes. Furthermore, the textiles used can be made from recycled materials or renewable resources reducing the ecological footprint .

The interplay of sustainable construction and appealing aesthetics demonstrates that textile architecture can be a promising, environmentally friendly alternative, paving the way for the future of the construction industry. It is now up to architects, with their networks and new projects, to drive the further development of textile architectural products and thus make our planet more sustainable.

Challenges in the use of textiles in the construction industry

The assembly and processing of textile building components requires special expertise, as the materials must be both delicate and durable.

Close collaboration between architects, construction companies and specialists in textile architecture is essential to ensure a harmonious integration of textiles into the construction industry.

One of the biggest challenges in using textiles in the construction industry is long-term durability and resistance to environmental influences . Building envelopes made of textile materials must not only be robust and weather-resistant, but also offer a high degree of flexibility and adaptability.

Furthermore, architects and planners must take into account that textiles must also meet high fire protection standards in order to guarantee the safety of buildings and their users.

Final words

In conclusion, the fusion of textile architecture and art represents a fascinating development. Textile architecture is more than just a functional element with a strong sustainability aspect; it is rather a creative form of expression.

The examples mentioned demonstrate how textile architecture is brought to life as a work of art on buildings, and how color, pattern, and light play a role in this process. We also considered the aesthetic impact of textiles within an architectural context.

The use of textiles in the construction industry presents challenges, but also significant advantages, such as flexibility and ease of handling. Furthermore, the question arises whether textile architecture represents an environmentally friendly alternative when it comes to sustainability.

With all these exciting aspects, architects transform buildings into artistic masterpieces and have ushered in a new era of architecture over the last few decades, which, thanks to constant technological change and the emergence of organic building materials, still holds so much untapped potential.

We can look forward to what the future holds for this industry…

Sources and references

Here you will find links to references that you can link to in your blog to improve domain authority, PageRank, relevance and overall SEO performance by generating traffic and increasing visibility.

- textile-architektur.de , a network of leading companies in membrane construction, https://www.textile-architektur.de/

- ALLPLAN Blog , https://blog.allplan.com/de/textile-architektur

- Architonic , a seal of approval for selected high-quality design products, materials, and architectural projects, https://www.architonic.com/de/story/susanne-fritz-bau-stoff-textile-architektur-teil-1/7000625

- rimpf Architekten , https://www.rimpf.de/portfolio/mitoseum_saurierpark_kleinwelka_bautzen/

- german-architects.com , Primordial Cell and Mitosis, https://www.german-architects.com/de/architecture-news/bau-der-woche/urzelle-und-mitose

- Pina GmbH , Sail-shaped roofing: From textile architecture to membrane construction, https://www.pina-design.de/informationen/blog/textile-architektur-membranbau

Owner and Managing Director of Kunstplaza. Publicist, editor, and passionate blogger in the field of art, design, and creativity since 2011. Successful completion of a degree in web design as part of a university program (2008). Further development of creativity techniques through courses in free drawing, expressive painting, and theater/acting. Profound knowledge of the art market through many years of journalistic research and numerous collaborations with actors/institutions from art and culture.

You might also be interested in:

Search

Similar posts:

Beliebte Kategorien

- Sculpture

- Design

- Digital Art

- Photography

- Freelancing

- Garden Design

- Interior Design

- Kreative Geschenke

- Creativity

- Art Periods And Movements

- Art History

- Art Trade

- Artists

- Art Marketing

- Art Market Knowledge

- Painting

- Music

- News

- Street Art / Urbane Kunst

- Tipps für Kunsthändler

- Tips for Artists

- Trends

- Living from art

Highlighted artwork

Design and Decor Highlights

-

J-Line abstract aluminum figure "Two Faces" on a black base

149,00 €

J-Line abstract aluminum figure "Two Faces" on a black base

149,00 €

inkl. MwSt.

Delivery time: 2-3 working days

-

Tribal decoration "Small Shell chain 2" in the ethno style

35,00 €

Tribal decoration "Small Shell chain 2" in the ethno style

35,00 €

inkl. MwSt.

Lieferzeit: 1-3 Werktage

-

J-Line reversible cushion “Scintillant” with opulent sequins (black/silver)

27,95 €

J-Line reversible cushion “Scintillant” with opulent sequins (black/silver)

27,95 €

inkl. MwSt.

Delivery time: 1-2 working days

-

Coastal Bohemian Interior wall mirror "La Principessa", abaca fibers, natural

219,95 €

Coastal Bohemian Interior wall mirror "La Principessa", abaca fibers, natural

219,95 €

inkl. MwSt.

Delivery time: 1-4 working days

-

J-Line Human Sculpture with Open Arms, Resin (Beige)

139,00 €

J-Line Human Sculpture with Open Arms, Resin (Beige)

139,00 €

inkl. MwSt.

Lieferzeit: 2-4 Werktage

-

J-Line Luxuriöses 1-Sitzer Sofa mit Knopfheftung, schwarzer Veloursamtbezug und goldfarbenes Metallgestell

1.250,00 €

J-Line Luxuriöses 1-Sitzer Sofa mit Knopfheftung, schwarzer Veloursamtbezug und goldfarbenes Metallgestell

1.250,00 €

inkl. MwSt.

Lieferzeit: 2-4 Werktage

-

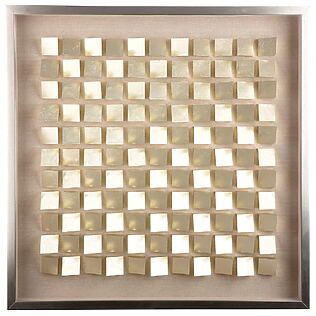

Luxurious 3D wall object "Rise", framed behind glass (champagne-gold colored)

Luxurious 3D wall object "Rise", framed behind glass (champagne-gold colored)

205,00 €The original price was: €205.00185,00 €The current price is: €185.00.inkl. MwSt.

Delivery time: 4-8 working days